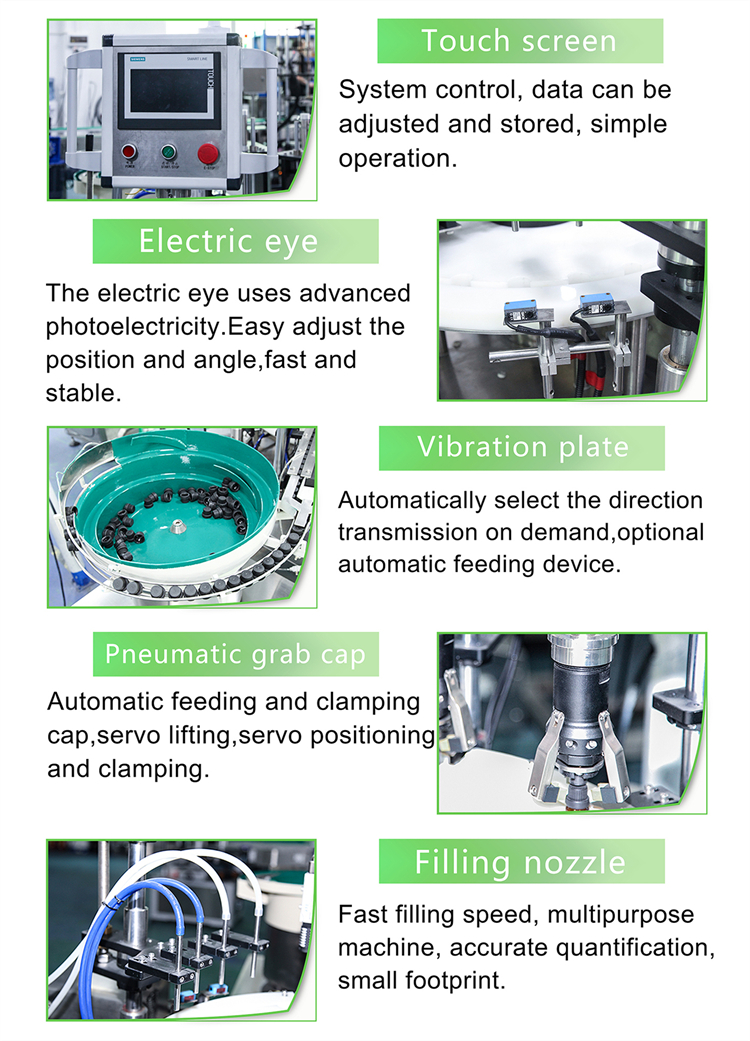

Dtnx-60xb multifunctional + essential oil filling capping machine

-

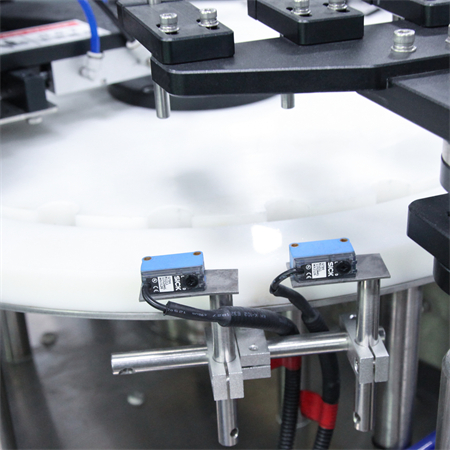

The dropper cap filling and capping machine includes several main steps: rotary table bottle feeding, automatic filling, automatic nozzle cap (dropper cap), capping, labeling and bottle receiving.

-

It is divided into bottle turntable feeding, peristaltic pump filling, bottle caps feeding, pre rotating capping, servo rotating capping, labeling, bottle collection and other operations.

1. Loading capacity: 5-100ml

2. Output: 30-40bpm

3. Loading accuracy: ≥ 99%

4. Yield of upper cover and inner plug: ≥ 99%

5. Capping yield: ≥ 99%

6. Host power: 2kW 220V

7. Labeling accuracy: ± 1mm